As a family-run company, we have a long-term commitment to environmental and energy management. The pursuit of sustainable management and the prudent use of resources are corporate goals equally as important to us as our social and economic objectives.

The company is certified in accordance with the ISO 14001:2015 environmental management system.

Furthermore, by employing an external energy management audit compliant with DIN EN 16247-1, we have systematically analysed our energy use and consumption. The potential for improvement revealed by this analysis effectively contributed to the further optimisation of our energy consumption and a corresponding decrease in our environmental impact.

Environmental Protection Measures:

The use of renewable energies is by far the most important contribution which can be made to the reduction in greenhouse gases. For this reason, we commissioned our photovoltaic system as early as 2008 and later expanded it to a total of 435 kWp.

The electricity generated by the company’s own photovoltaic system thus reduces the burden on the environment by approximately 260 tonnes of CO2 per year with up to 77% of the output being consumed by the company itself. All the surplus electricity produced is fed into the public grid.

Since 2008, this has saved approximately 2000 tonnes of CO2 in total (as of January 2023).

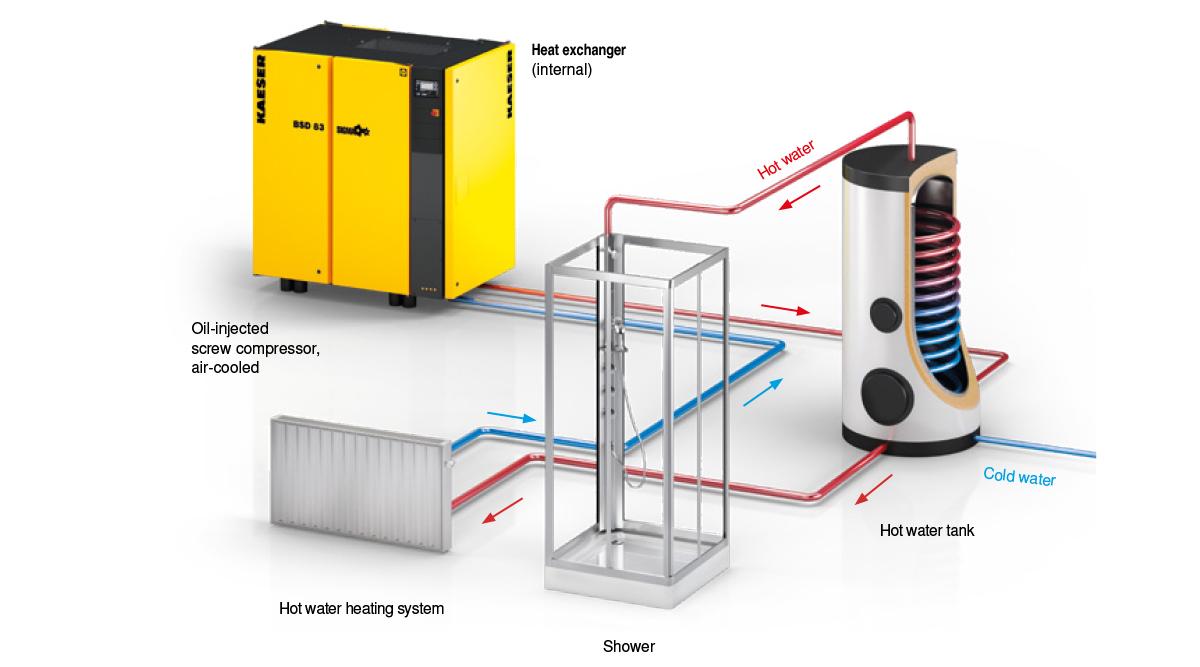

To save further emissions, we use a heat recovery system. It utilizes the waste heat from the machines and compressors and feeds it back into the heating system. This heat is used for the entire heating system, including service water.

The heat recovery system enables us to save 120 tons of CO2 per year.

Our remaining heating demands are met through bioenergy. Wood is one of the most important renewable raw materials in the field of bioenergy fuel.

Thus, our woodchip plant also contributes to sustainable building management with wood waste/chips being used to heat the production and administration buildings.

By generating heat with bioenergy (wood chips), we achieve a CO2 saving of 62 tonnes per year compared to burning fossil fuels (petroleum).

Our waste management strategy follows the goals of avoidance, recovery, recycling and professional disposal of waste in accordance with legal requirements and the maxims of sustainability.

All recyclable materials (metal, plastic, paper products, glass, etc.) are collected by a specialised company and recycled.

However, while much the production of non-recyclable waste can be reduced, it cannot be totally avoided; therefore we ensure that this is disposed of in a professional and responsible manner.

Our contribution to CO2 reduction through the use of alternative energies totals 442 tonnes of CO2 per year

Outlook for the Future:

2024 | Construction of a new hall and expansion of the photovoltaic system

2024 | Certification of the environmental management system according to ISO 14001

Review of our Environmental and Energy Projects:

2022 | Energy audit in accordance with DIN EN 16247-1 by Wolff & Müller Energy to determine potential further energy efficiency, including an implementation programme

2018 | Replacement of pumps with more efficient environmental pumps

Acquisition of a highly efficient air compressor with heat recovery

2015 | Optimisation of all lighting to LED bulbs (resulting in a 60% electricity saving)

2014 | Implementation of an external energy audit in accordance with SpaEfV by EQ-ZERT